Reimagining Training

Opportunities and Pain Points

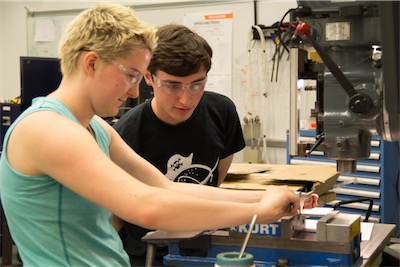

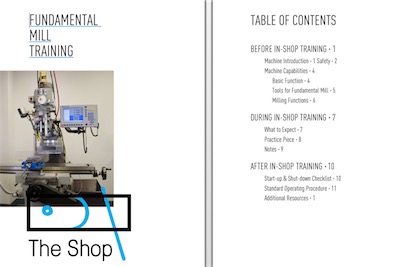

Students' understanding of the training process and purpose is currently unclear. Training procedures can vary for different pieces of equipment. In some cases, there is a pre-reading and a quiz; for others, no preparation is required. Some trainings involve multiple sessions and a prescribed test part; others are short and do not require the fabrication of a final test artifact. The purpose of training is not always clear. Is it learning? Demonstrating competence? Effectively limiting access? Finally, students sometimes have a hard time learning about what's available to them in The Shop and how they can get trained to use whatever resources they need to complete a project.

The greatest impacts of a successfully revised training system will be more student activity in the space, a strengthened culture of safety, and improved project outcomes for course, personal, and student club projects.

Goals

- Develop a continuous improvement mindset - An improved training process should help students to develop a mindset of continuous improvement. We want students to and embrace the fact that training is not a process that ends. Being &ldquol;trained” is a certification that a student can safely operate a machine, but training is a continuous and ongoing learning process.

- Minimize barriers - The training process should minimize barriers to getting started. Every checkpoint, deliverable, or test should come with a strong justification for how it improves the learning process or training outcome.

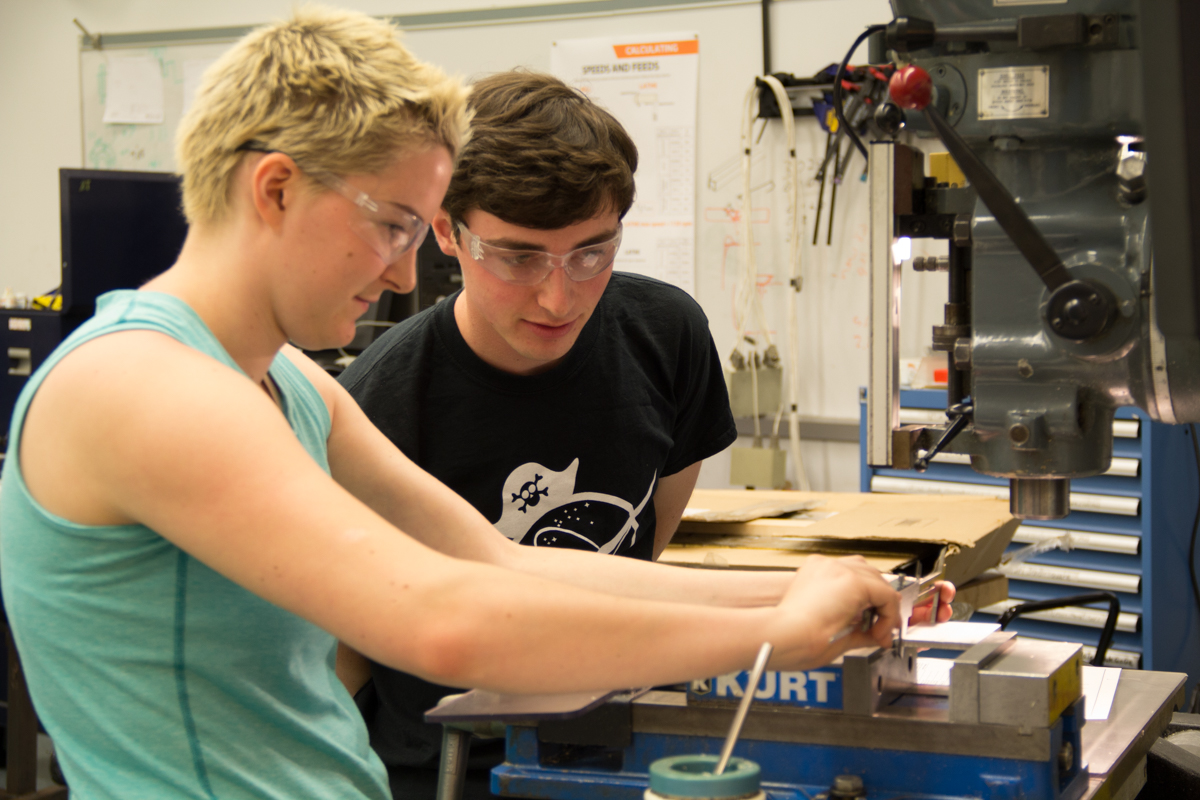

- Build confidence - We want users of the The Shop to walk away from a training experience feeling more confident in their abilities rather than scared or with a message reinforcing a self-perception that they “don't belong.”

- Increase transparency - The training system should be transparent. I should be obvious how one gets training and what kind of committment training on each piece of equipment requires.

- Be exciting and welcoming - The process of training should be exciting for the user. They should be able to see a path to completing a project that they're passionate about. We would like training to open up a world of possibility and show them how powerful turning their ideas into physical reality can be.

- Encourage curiosity - Training is just the first glimpse into what is possible. Students should be encouraged to ask questions throughout the process and (especially) afterward.

Tensions and Challenges

- Welcoming vs. accommodating demand - We want the process to be as friendly and welcoming as possible, but we also recognize that time is a finite resource. If we are successful in making the process open, transparent, and welcoming, we expect to encounter challenges meeting the demand from community members. This, however, is a good problem to have.

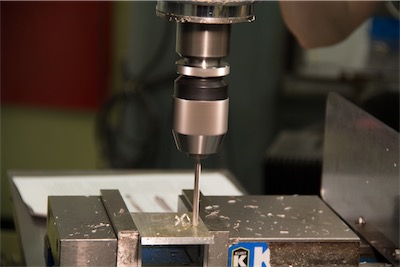

- Efficient production vs. learning - Often times, making something yourself is not the most efficient way to arrive at a functional artifact. Certainly, making something using a process on which you've only just been trained is likely to be punctuated by frequent errors. However, it's in the making of those mistakes that the learning is most powerful. Our training approaches and supporting processes will need to strike a delicate balance between facilitating learning (and the attendant making of mistakes) and enabling efficient production of artifacts.

- Building confidence vs. overconfidence - We want students to walk away from a training

experience feeling more confident in their abilities. However, we need to be careful to impress upon them

the importance of basic safety practices like wearing personal protective equipment, properly handling

and securing their workpieces, and asking questions when they don't know how to do something. This tension goes

hand-in-hand with our goal of developing lifelong learners who adopt a continuous improvement mindset.

Metrics for Success

One very simple and straightforward metric of success will be the number of successfully completed trainings in a given semester or year. (It is probably preferable to use a full year to avoid seasonal variation due to course or project team schedules.) Another way to measure success might be comparing the number of aborted trainings in years past to the number of aborted trainings after the new system is implemented.